The Foundation of Construction: Understanding the Rebar Cutting Machine

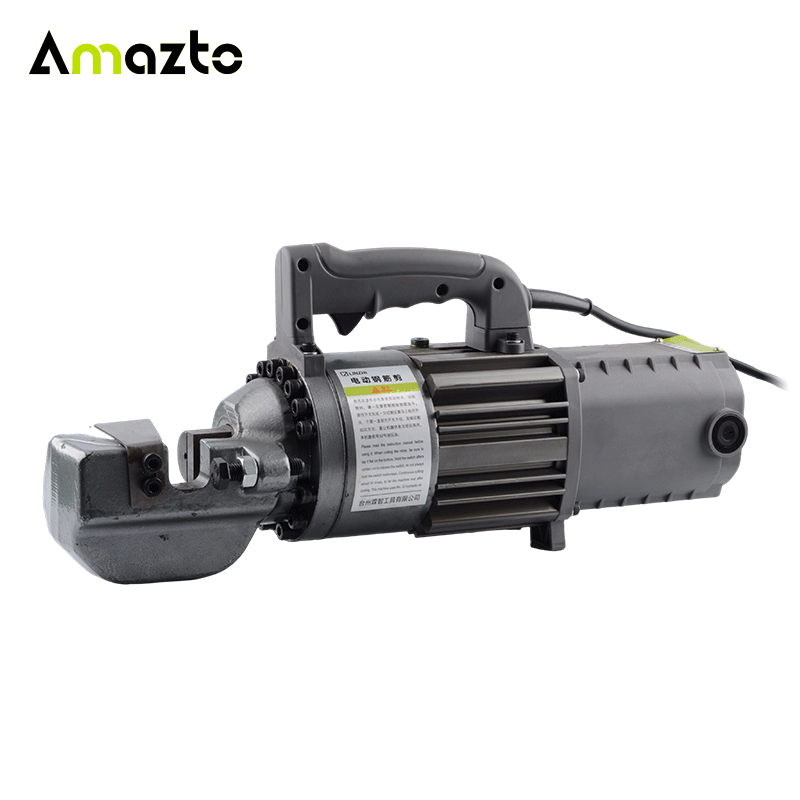

A rebar cutting machine is a fundamental piece of equipment on construction sites and in steel fabrication yards, designed to sever reinforcing steel bars to specified lengths with accuracy and speed. This machine addresses the critical need for precise rebar preparation, which is essential for the structural integrity of concrete frameworks in buildings, bridges, and other infrastructure projects. By automating a task that would otherwise be labor-intensive and inconsistent, the rebar cutting machine ensures material efficiency and adherence to engineering specifications.

The operation of a rebar cutting machine typically involves a hydraulic or mechanical shear system. The rebar is fed into a cutting head where a powerful blade descends to create a clean, perpendicular cut without crushing or deforming the steel. Modern machines often incorporate numerical controls or programmable logic controllers (PLCs), allowing operators to input exact cut lengths and quantities. This automation minimizes human error and material waste, transforming long stock lengths into ready-to-use pieces for tying and assembly into rebar cages.

Safety and productivity are paramount considerations when using this equipment. Operators must follow procedures to secure the rebar and keep hands clear of the shear mechanism, with many machines featuring protective guards and two-handed start controls. Regular maintenance of the blades and hydraulic systems preserves cutting accuracy and operational reliability. The indispensable role of a rebar cutting machine lies in its ability to deliver consistent, high-volume output, forming the first crucial step in transforming raw steel into the reinforced skeleton of modern construction.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- الألعاب

- Gardening

- Health

- الرئيسية

- Literature

- Music

- Networking

- أخرى

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness