How Operators Maintain Steady Performance in Metal Sawing Workc

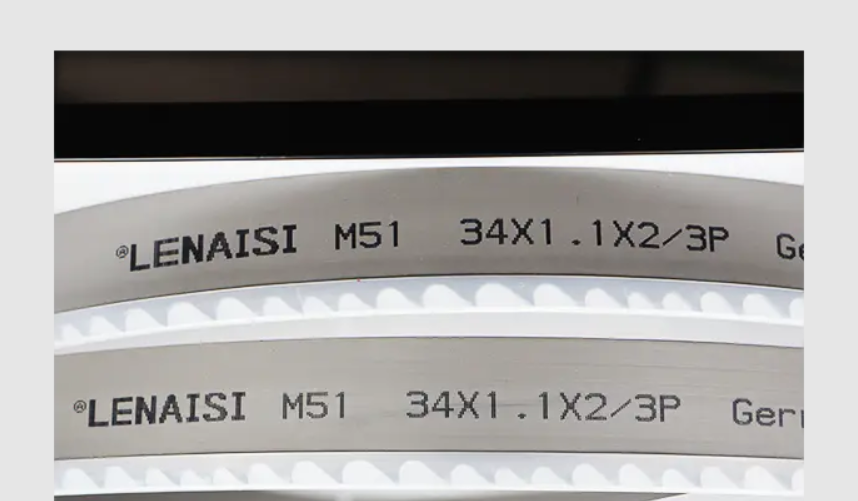

Many workshops begin their day by setting up equipment such as a Metal Cutting Band Sawing Machine and installing an M42 Bi-Metal Band Saw Blade to prepare for a full schedule of cutting tasks. The first minutes of setup often shape the rhythm of the entire shift. Technicians check blade tension, inspect coolant flow, and secure workpieces before initiating the first cut. These early steps influence how smoothly the machine operates once the blade meets the material.

Cutting various metals involves observing how the blade reacts to changes in thickness, hardness, or structure. Solid round bars require careful feed control because the blade encounters increasing resistance as it moves toward the center. Tubes with thinner walls behave differently, often producing lighter chips and requiring a more measured entry to avoid tooth snagging. The machine’s feeding behavior helps maintain stability through these transitions.

Operators often talk about the “feel” of the cut. This refers to the subtle combination of machine vibration, blade sound, and resistance from the material. A cut that feels balanced suggests good alignment between blade and guides. A slight sideways pull may indicate improper clamping or shift in blade tension. Keeping an attentive ear helps operators make timely adjustments.

Coolant distribution contributes significantly to blade life. When coolant flows evenly across the cutting zone, temperature remains manageable and chips move away efficiently. Workshops where coolant nozzles become partially blocked often experience higher blade wear. Regular cleaning helps maintain a stable operating environment. Heat buildup not only dulls teeth but can also affect the surface of the workpiece.

Chip color and shape provide immediate feedback. Blue-tinted chips usually mean the blade is running hotter than intended. Silver or light gray chips are more common during stable cutting. Short, fractured chips may point to insufficient feed pressure. By learning to recognize these details, technicians strengthen their ability to guide the saw through different materials.

The machine’s mechanical components affect cutting consistency as well. Guide rollers help maintain blade stability, and their bearings require periodic lubrication. A worn guide may allow the blade to twist slightly under load, producing an uneven surface finish. Drive wheels also need cleaning to prevent debris buildup, which can influence tracking. The cumulative effect of these maintenance routines becomes noticeable over long-term use.

Choosing the correct blade pitch is part of everyday planning. Coarse-tooth blades remove chips quickly but require solid material engagement. Fine-tooth blades suit thinner sections and reduce vibration during entry. When matched correctly, pitch selection supports smoother cutting and reduces operator intervention. Blade manufacturers often provide reference charts, but workshops typically refine these suggestions based on their own material types.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Juegos

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness