Optical Performance Advances in Ultra-Clear PVC Materials

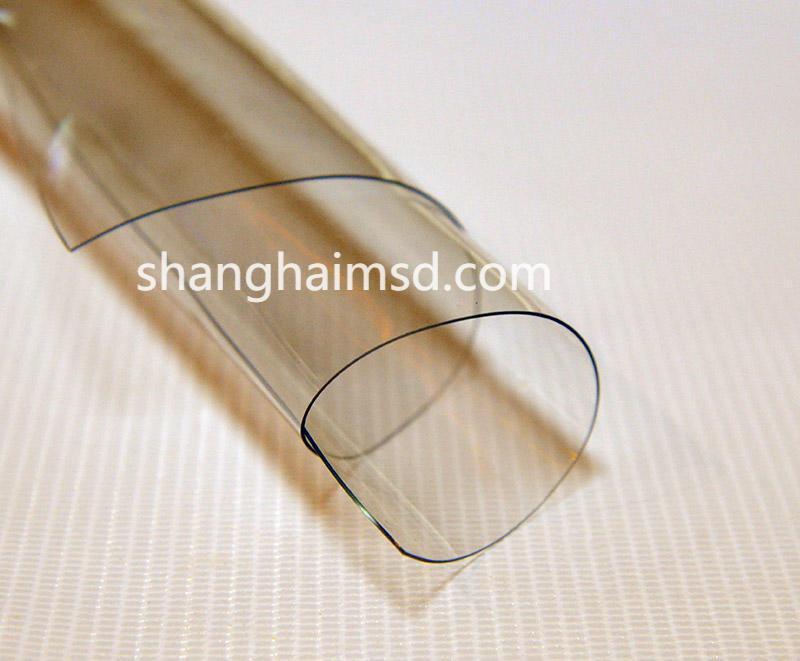

The demand for highly transparent polymer materials has grown significantly across packaging, consumer goods, and protective applications, and one material that consistently meets strict clarity and durability standards is PVC Super Clear Film. This advanced film category is widely distributed by Shanghai Mingshida International Trading Co., Ltd., which has developed expertise in identifying formulas and production techniques that deliver exceptional visual and mechanical performance for industries requiring precise transparency and stability.

PVC-based clear films exhibit a unique balance of flexibility, optical purity, and controlled rigidity due to their polymer chain structure and the use of high-grade plasticizers. Unlike general-purpose PVC films, ultra-transparent versions rely on precision compounding to minimize haze and reduce internal micro-defects that scatter light. The resin selection plays a crucial role, as higher-purity vinyl chloride polymers combined with refined stabilizers enhance thermal consistency during processing. Heat-resistant additives, anti-yellowing agents, and slip modifiers are also calibrated to preserve clarity without compromising softness or tensile strength.

During manufacturing, the film typically undergoes calendaring or extrusion, both of which require strict control of melt temperature, cooling rate, and roller pressure. Calendaring allows multiple rollers to stretch and flatten the material into a uniform sheet, maintaining clarity by eliminating air bubbles and micro-void formations. Extrusion, on the other hand, offers continuous production with narrower thickness tolerances when cooling is precisely managed. Shanghai Mingshida International Trading Co., Ltd. works with facilities that prioritize equipment calibration, ensuring that roller alignment and extrusion die flow remain consistent to prevent optical distortion across the film width.

One of the notable characteristics of high-grade transparent PVC film is its gloss. Achieving a mirror-like finish requires fine polishing of rollers and accurate temperature profiling to keep the surface smooth and defect-free. When raw materials are filtered through micro-screen meshes before entering the melt phase, impurities remain minimal, further enhancing the film’s optical performance. Additionally, surface treatments such as corona discharge may be applied to increase surface energy for printing and lamination, extending the film’s usability across versatile manufacturing lines.

In terms of mechanical properties, ultra-clear PVC films maintain a desirable balance between elasticity and form stability. They can endure bending without whitening, a common issue caused by stress concentration in lower-quality films. Impact resistance is significantly improved through optimized plasticizer ratios and the addition of reinforcing agents that strengthen polymer entanglement. Shrinkage control is essential, especially for applications requiring dimensional accuracy. When the film undergoes controlled stretching during production, molecular orientation contributes to predictable shrinkage behavior under heat or prolonged stress.

These films serve diverse application sectors. In packaging, they are used for display windows, cosmetic pouches, stationery covers, and medical accessories requiring visual inspection of contents. In consumer goods, they appear in protective sleeves, transparent organizers, inflatable products, and home furnishing components. High-clarity film is also used in industrial settings such as instrument panels or protective overlays for machine surfaces that need visibility without exposure to contaminants. The ability to combine transparency with durability allows manufacturers to create aesthetically appealing yet functionally reliable products for both mass and specialty markets.

Comprehensive performance testing is essential to ensure that each batch meets optical and mechanical standards. Haze measurement determines how much light scattering occurs through the film, while transparency tests evaluate luminous transmittance using standardized illumination. Tensile and tear resistance tests assess performance under mechanical load, and dimensional stability testing ensures minimal deformation during heat exposure. Additional evaluations, such as migration testing and anti-yellowing assessment under UV conditions, confirm the film’s suitability for consumer or industrial environments that demand prolonged clarity and safety.

Shanghai Mingshida International Trading Co., Ltd. continues to support global manufacturers by supplying material solutions that meet evolving clarity, formability, and compliance requirements. More details on transparent PVC film applications and industry insights can be found at https://www.shanghaimsd.com/news/industry-news/pvc-super-clear-film-the-ultimate-transparent-solution-for-versatile.html .

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Giochi

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Altre informazioni

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness