Packaging Automation: Unlocking Speed, Accuracy, and Flexibility

The global packaging machinery market is entering a new era shaped by automation, intelligent technologies, and evolving consumer demands. As manufacturers across food, pharmaceuticals, personal care, and e-commerce sectors strive to improve efficiency and consistency, packaging machinery has become a strategic investment rather than a supporting asset. In 2024, the market was valued at US$ 54.5 billion and is projected to reach US$ 90.1 billion by 2035, growing at a CAGR of 4.7% from 2025 to 2035.

This steady growth reflects how packaging operations are being redefined—from labor-intensive processes to digitally optimized, high-throughput production systems.

The Role of Packaging Machinery in Modern Manufacturing

Packaging machinery covers a wide range of equipment designed to automate filling, sealing, labeling, wrapping, and cartoning of products. These systems are used across industries handling liquids, powders, solids, and pastes, enabling manufacturers to meet safety regulations, improve product presentation, and scale production efficiently.

With increasing pressure on margins and persistent labor shortages, companies are adopting semi-automatic and fully automated packaging lines to ensure consistency, speed, and cost control. At the same time, integration with smart systems allows real-time monitoring, data analysis, and predictive maintenance—features that are now becoming standard expectations rather than optional upgrades.

Automation as a Core Growth Driver

One of the strongest drivers of the packaging machinery market is the rising demand for automated packaging solutions. Automation reduces manual handling, minimizes contamination risks, improves workplace safety, and ensures stable output even during labor constraints. Modern plants are increasingly equipped with sensors, vision systems, and connected software that help identify potential issues before they disrupt production.

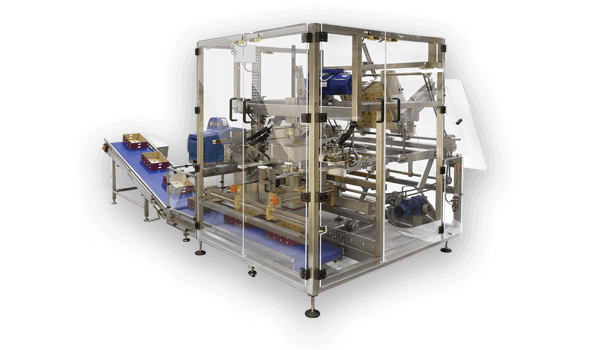

Form-fill-seal (FFS) systems are at the center of this transition. These machines can form a package from roll stock, fill it with product, and seal it in a single continuous operation. Their ability to handle multiple pack formats with minimal changeover has made them particularly attractive to food processors and pharmaceutical manufacturers seeking flexibility and speed.

Download Sample PDF Copy Now: https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=3076

Robotics and AI Reshaping Packaging Lines

Investment in robotics and AI-powered packaging systems has moved from experimental to mainstream. Robotic pick-and-place units, combined with machine vision and force-feedback technology, are enabling precise handling of delicate and irregular products. These systems are faster, more consistent, and increasingly safe to operate alongside human workers.

AI and machine learning are being used to detect anomalies in sealing and filling accuracy, balance line speeds dynamically, and optimize energy consumption. Digital twins are also gaining traction, allowing manufacturers to simulate packaging lines virtually and reduce commissioning time before physical installation. These software-driven improvements are unlocking higher output without major mechanical changes.

Filling & Dosing/Form-Fill-Seal Leads by Product Type

By product type, filling & dosing/form-fill-seal systems dominated the market in 2024, accounting for 29.9% of global revenue. Their leadership stems from versatility, compact footprints, and compatibility with high-speed inspection and compliance tools such as checkweighers and vision systems. As demand grows for single-serve, ready-to-eat, and convenience products, FFS systems are expected to retain their dominant position.

Asia Pacific at the Forefront

Regionally, Asia Pacific led the packaging machinery market with a 37.4% share in 2024. Strong manufacturing bases in China, India, Japan, and Southeast Asia, combined with rising consumption of packaged food and pharmaceuticals, continue to drive equipment demand. Government initiatives supporting food processing and local manufacturing further strengthen the region’s leadership.

Looking Ahead

As automation, sustainability, and digital intelligence converge, packaging machinery will remain a critical enabler of competitive manufacturing. With continuous innovation from players such as Bosch, Tetra Pak, Coesia, Marchesini Group, and IMA, the industry is well positioned to support the next decade of growth—delivering faster, smarter, and more efficient packaging solutions worldwide.

Contact Us:

Transparency Market Research Inc.

CORPORATE HEADQUARTER DOWNTOWN,

1000 N. West Street,

Suite 1200, Wilmington, Delaware 19801 USA

Tel: +1-518-618-1030

USA - Canada Toll Free: 866-552-3453

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jogos

- Gardening

- Health

- Início

- Literature

- Music

- Networking

- Outro

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness