-

Fil d’actualités

- EXPLORER

-

Pages

-

Groupes

-

Evènements

-

Reels

-

Blogs

Future Trends in the Progressing Cavity Pump Market

Introduction

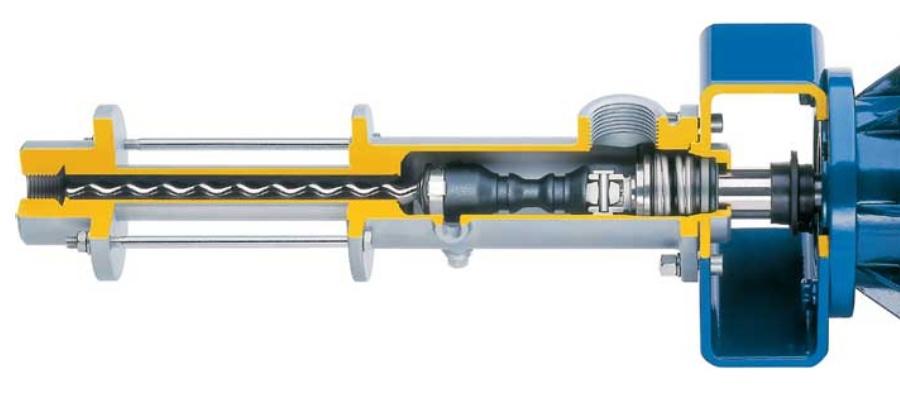

The Progressing Cavity Pump Market is a key segment of the positive displacement pump industry, supplying pumping solutions designed to handle viscous, abrasive, shear-sensitive, and solids-laden fluids with consistent flow and low pulsation. Progressing cavity pumps operate using a helical rotor turning within a stator, creating sealed cavities that move fluid smoothly from suction to discharge. This operating principle makes them ideal for demanding applications across oil and gas, wastewater treatment, mining, food and beverage, chemicals, pulp and paper, and renewable energy sectors such as biogas. As industries prioritize reliability, efficiency, and process stability, progressing cavity pumps continue to gain importance in critical fluid handling operations.

Market Drivers

A primary driver of the Progressing Cavity Pump Market is the growth of wastewater and sludge management activities. Municipal and industrial wastewater treatment plants rely heavily on progressing cavity pumps to handle thick sludge, biosolids, and chemically aggressive fluids without clogging or excessive wear. Increasing urbanization, stricter environmental regulations, and investment in water infrastructure are directly supporting demand for these pumps.

Expansion in the oil and gas industry is another major driver. Progressing cavity pumps are widely used in upstream applications for artificial lift, as well as in midstream and downstream operations for handling viscous crude, emulsions, and multiphase fluids. Their ability to maintain steady flow at varying pressures makes them well suited for challenging oilfield conditions, supporting continued adoption.

Industrial process growth also fuels market expansion. Industries such as chemicals, mining, food processing, and pulp and paper require precise, low-shear pumping for sensitive or abrasive materials. Progressing cavity pumps provide accurate dosing, gentle handling, and reliable performance, making them preferred solutions in process-critical environments.

Market Challenges

Despite strong demand, the Progressing Cavity Pump Market faces several challenges. One of the key issues is wear and maintenance of elastomer stators. Fluids with high abrasiveness, temperature extremes, or chemical aggressiveness can accelerate stator degradation, leading to increased maintenance costs and downtime if not properly managed.

Higher initial cost compared to centrifugal pumps is another challenge. Progressing cavity pumps are more complex in design and typically have higher upfront costs, which can discourage adoption in cost-sensitive applications where simpler pumping solutions may appear adequate.

Operational sensitivity also presents challenges. Dry running, excessive pressure, or incorrect speed control can damage pump components. This requires proper system design, monitoring, and operator training to ensure long-term reliability.

Market Opportunities

Technological advancement offers significant opportunities for the Progressing Cavity Pump Market. Innovations in elastomer materials, rotor coatings, and wear-resistant designs are extending pump life and improving performance in aggressive applications. These improvements reduce total cost of ownership and make progressing cavity pumps more attractive for continuous-duty operations.

The rise of renewable energy and biogas production presents new growth opportunities. Progressing cavity pumps are well suited for handling biomass slurries, digestate, and feedstock materials in anaerobic digestion systems. As governments invest in renewable energy and circular economy solutions, demand for reliable pumps in these applications is increasing.

Digitalization and condition monitoring also create market opportunities. Pumps equipped with sensors, variable frequency drives, and monitoring systems enable predictive maintenance, speed optimization, and early fault detection. These smart pump solutions improve reliability and reduce unplanned downtime, particularly in remote or critical installations.

Regional Insights

Europe represents a major market for progressing cavity pumps, driven by strong wastewater treatment infrastructure, environmental regulations, and adoption in food processing and renewable energy applications. The region emphasizes energy efficiency, sustainability, and high-quality industrial equipment.

North America is another significant market, supported by oil and gas activity, municipal water treatment investments, and industrial process demand. Adoption of advanced monitoring and automation technologies is particularly strong in the region.

Asia-Pacific is the fastest-growing market, fueled by rapid industrialization, expanding wastewater treatment capacity, and growth in mining and chemical processing industries. Countries such as China and India are investing heavily in infrastructure and industrial development, driving demand for robust pumping solutions.

Other regions, including Latin America, the Middle East, and Africa, are experiencing steady growth as water infrastructure, energy projects, and industrial activities expand.

Future Outlook

The Progressing Cavity Pump Market is expected to grow steadily as industries continue to handle more complex fluids and prioritize process reliability. Demand will increasingly focus on pumps that offer longer service life, improved efficiency, and reduced maintenance requirements.

Manufacturers will invest in material innovation, modular designs, and digital integration to enhance pump performance and ease of operation. Variable speed control and smart diagnostics will become standard features in high-value applications.

As sustainability and environmental compliance gain importance, progressing cavity pumps will play a critical role in wastewater treatment, sludge handling, and renewable energy processes, reinforcing their long-term relevance.

Conclusion

The Progressing Cavity Pump Market plays a vital role in enabling reliable and efficient handling of viscous, abrasive, and sensitive fluids across a wide range of industries. Driven by growth in wastewater treatment, oil and gas operations, and industrial processing, the market offers strong long-term potential. While challenges related to maintenance, cost, and operational sensitivity exist, technological innovation and expanding applications in renewable energy and smart infrastructure are strengthening the market’s outlook. Progressing cavity pumps will remain an essential component of modern fluid handling systems worldwide.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jeux

- Gardening

- Health

- Domicile

- Literature

- Music

- Networking

- Autre

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness