-

Новости

- ИССЛЕДОВАТЬ

-

Страницы

-

Группы

-

Мероприятия

-

Reels

-

Статьи пользователей

Safety and Reliability Trends in the Railway Wiring Harness Market

Introduction

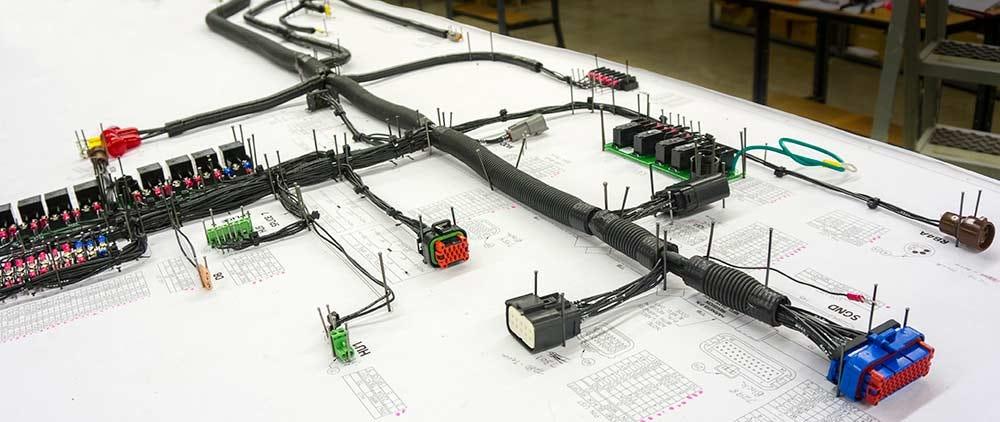

The Railway Wiring Harness Market is a vital segment of the railway components and electrical systems industry, supplying organized assemblies of wires, cables, connectors, terminals, and protective elements that distribute power and signals across rail vehicles. Wiring harnesses form the nervous system of trains, enabling reliable operation of propulsion, braking, lighting, HVAC, signaling, passenger information systems, safety controls, and onboard electronics. Used across locomotives, passenger coaches, metros, trams, and high-speed trains, railway wiring harnesses are engineered to withstand vibration, temperature extremes, moisture, electromagnetic interference, and long service lifecycles. As rolling stock becomes more electrified, digitalized, and passenger-centric, the importance of robust and intelligent wiring harness solutions continues to grow.

Market Drivers

A primary driver of the Railway Wiring Harness Market is the increasing electrification and digitalization of rail vehicles. Modern trains rely on extensive electrical and electronic systems to support traction control, braking, diagnostics, communication, and passenger services. This growing system complexity directly increases the length, density, and sophistication of wiring harnesses required per vehicle, driving steady demand across new builds and retrofits.

Expansion of urban transit systems is another major growth driver. Rapid urbanization is fueling investment in metros, light rail, and suburban rail networks worldwide. These systems require highly reliable wiring harnesses capable of handling frequent start-stop cycles, high passenger loads, and continuous operation. Large-scale procurement of metro rolling stock significantly boosts demand for standardized and modular wiring harness assemblies.

Fleet modernization and refurbishment further support market growth. Many rail operators are upgrading aging rolling stock to improve energy efficiency, safety, and passenger comfort. Retrofitting modern electrical systems often requires replacement or reconfiguration of wiring harnesses, creating strong aftermarket and service demand in addition to new vehicle production.

Market Challenges

Despite strong demand, the Railway Wiring Harness Market faces several challenges. Design complexity is a key issue, as wiring harnesses must be tailored to specific vehicle platforms, power architectures, and regulatory standards. Customization increases engineering effort, extends development timelines, and limits economies of scale for manufacturers.

Harsh operating environments also present challenges. Railway wiring harnesses are exposed to vibration, heat, moisture, chemicals, and electromagnetic interference. Ensuring long-term reliability under such conditions requires high-quality materials, advanced insulation, and rigorous testing, all of which increase production costs.

Compliance with safety and fire standards adds further complexity. Railway wiring harnesses must meet strict requirements related to flame retardancy, smoke emission, and toxicity to ensure passenger safety in the event of fire. Adhering to multiple regional standards increases certification costs and complicates global supply strategies.

Market Opportunities

Technological innovation offers significant opportunities in the Railway Wiring Harness Market. The shift toward lightweight materials and optimized cable routing helps reduce overall vehicle weight, improving energy efficiency and performance. Advanced insulation materials and compact connector designs enable higher power density while maintaining safety and durability.

The rise of smart trains and digital rail systems creates new growth avenues. Wiring harnesses increasingly integrate data communication lines for sensors, control systems, and passenger information platforms. Harnesses designed to support high-speed data transmission and diagnostics enable predictive maintenance and real-time monitoring, enhancing operational reliability and reducing downtime.

Standardization and modularization present additional opportunities. Modular wiring harness architectures allow faster assembly, easier maintenance, and simplified upgrades. As rolling stock manufacturers seek to reduce production complexity and lifecycle costs, demand for standardized and scalable wiring harness solutions is expected to grow.

Regional Insights

Asia-Pacific dominates the Railway Wiring Harness Market, driven by extensive rail network expansion, metro rail development, and high rolling stock production volumes. Strong manufacturing ecosystems and government investment in rail infrastructure support sustained demand across the region.

Europe represents a mature and technology-driven market. The region emphasizes safety, interoperability, and sustainability, driving demand for high-quality wiring harnesses that meet stringent fire and performance standards. Ongoing fleet upgrades and cross-border rail operations sustain market activity.

North America shows steady growth, supported by investments in urban transit, commuter rail modernization, and upgrades to passenger rail fleets. Demand is largely driven by refurbishment projects and integration of advanced onboard systems.

Other regions, including Latin America, the Middle East, and Africa, are gradually expanding rail infrastructure and urban transit networks, contributing to long-term market growth as rail becomes a strategic mode of transport.

Future Outlook

The Railway Wiring Harness Market is expected to grow steadily as rail systems become more electrified, connected, and automated. Increasing integration of digital technologies, onboard diagnostics, and passenger-centric features will continue to raise wiring complexity and value per vehicle.

Future developments will focus on lightweight designs, higher power and data capacity, and improved resistance to environmental stress. Manufacturers will invest in automation, digital design tools, and advanced testing to improve quality and reduce production lead times.

As sustainability gains importance, eco-friendly materials and recyclable components will also influence product development. Wiring harness solutions that balance performance, safety, and environmental impact will gain competitive advantage.

Conclusion

The Railway Wiring Harness Market is a critical enabler of modern rail vehicle functionality, safety, and reliability. Driven by electrification, urban transit expansion, and rolling stock modernization, the market offers stable long-term growth potential. While challenges related to customization, harsh operating conditions, and regulatory compliance persist, technological innovation and modular design approaches are strengthening market prospects. As rail systems evolve toward smarter and more connected platforms, high-quality wiring harnesses will remain essential to the efficient and safe operation of global rail networks.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Игры

- Gardening

- Health

- Главная

- Literature

- Music

- Networking

- Другое

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness