-

Fil d’actualités

- EXPLORER

-

Pages

-

Groupes

-

Evènements

-

Reels

-

Blogs

Why Vibration Mitigation Is Critical for Modern Infrastructure

Introduction

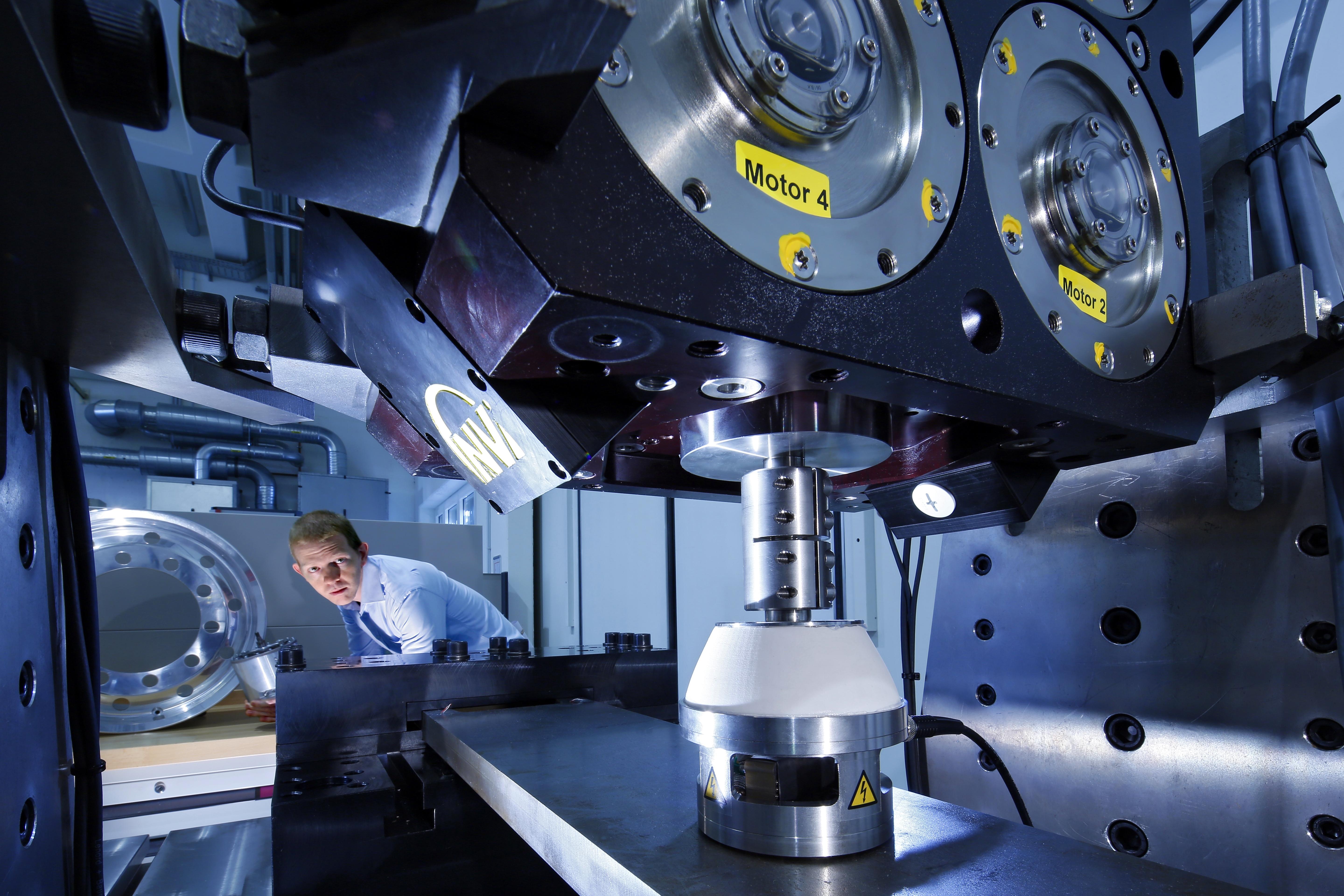

The vibration control system market is a critical segment of the industrial engineering and infrastructure ecosystem, focused on minimizing unwanted vibrations that can affect structural integrity, equipment performance, and human comfort. Vibration control systems include devices and solutions such as isolators, dampers, mounts, absorbers, and vibration monitoring technologies designed to reduce or manage vibrations in machinery, buildings, vehicles, and industrial processes. These systems are widely used across construction, manufacturing, automotive, aerospace, energy, and transportation sectors.

As industrial equipment becomes more powerful and structures more complex, controlling vibration has become essential for safety, durability, and operational efficiency. Excessive vibration can lead to equipment failure, increased maintenance costs, noise pollution, and reduced productivity. Growing emphasis on workplace safety, infrastructure resilience, and precision manufacturing is driving adoption of advanced vibration control solutions, supporting steady growth in the global vibration control system market.

Market Drivers

One of the primary drivers of the vibration control system market is rapid industrialization and expansion of heavy machinery usage. Manufacturing plants, power generation facilities, and process industries rely on large rotating and reciprocating equipment that generates significant vibration. Vibration control systems help protect machinery, extend service life, and ensure stable operation, making them essential components in modern industrial environments.

Growth in construction and infrastructure development is another major driver. High-rise buildings, bridges, rail networks, and commercial structures are increasingly designed to meet strict safety and comfort standards. Vibration control systems are used to mitigate structural vibrations caused by wind, seismic activity, traffic, and mechanical systems. Increasing urbanization and investment in smart and resilient infrastructure are strengthening demand for vibration control solutions.

The automotive and transportation sectors also contribute significantly to market growth. Vehicles, rail systems, and aircraft require effective vibration control to enhance ride comfort, reduce noise, and protect sensitive components. As vehicles become more technologically advanced and electric drivetrains gain popularity, demand for refined vibration and noise management solutions is increasing.

Market Challenges

Despite strong demand, the vibration control system market faces several challenges. High installation and customization costs can be a barrier, particularly for small and medium-sized projects. Vibration control solutions often need to be tailored to specific equipment, load conditions, and operating environments, increasing engineering complexity and project costs.

Technical complexity is another challenge. Designing effective vibration control systems requires detailed analysis of vibration sources, frequencies, and transmission paths. Inadequate system design or improper installation can reduce effectiveness and lead to performance issues, affecting customer confidence and project outcomes.

Maintenance and performance monitoring also pose challenges. Over time, vibration control components such as dampers and mounts may degrade due to wear, temperature fluctuations, or environmental exposure. Ensuring long-term reliability requires regular inspection and maintenance, which can increase operating costs for end users.

Market Opportunities

Technological advancements present significant opportunities for the vibration control system market. Integration of sensors, data analytics, and digital monitoring enables real-time vibration analysis and predictive maintenance. Smart vibration control systems allow operators to detect abnormal vibration patterns early, reducing downtime and preventing equipment failure.

Growth in renewable energy infrastructure offers another major opportunity. Wind turbines, solar tracking systems, and power generation equipment require effective vibration control to maintain stability and efficiency. As renewable energy installations expand globally, demand for advanced vibration mitigation solutions is expected to increase.

Emerging markets represent strong growth potential due to increasing industrialization and infrastructure investment. Developing regions are investing in manufacturing facilities, transportation networks, and urban development projects, all of which require vibration control solutions. Government initiatives supporting industrial modernization and infrastructure resilience are expected to further drive market expansion.

Regional Insights

Asia-Pacific holds a leading position in the vibration control system market due to rapid industrial growth and large-scale infrastructure development. Countries such as China, India, and Southeast Asian nations are investing heavily in manufacturing, transportation, and construction projects, driving strong demand for vibration control solutions.

North America represents another significant market, supported by advanced industrial infrastructure and strict safety and performance standards. Demand from aerospace, automotive, and energy sectors continues to support steady market growth. Increasing adoption of smart monitoring and predictive maintenance technologies is further strengthening market demand in the region.

Europe also contributes substantially to the market, driven by emphasis on sustainable infrastructure, high engineering standards, and strong industrial base. Adoption of vibration control systems in transportation, renewable energy, and advanced manufacturing applications is supporting market expansion across the region.

Future Outlook

The future of the vibration control system market is closely linked to trends in smart manufacturing, infrastructure resilience, and digitalization. Vibration control solutions are expected to become more intelligent, adaptive, and integrated with monitoring systems. Advances in materials science, such as high-performance elastomers and composite materials, will improve durability and performance.

As industries prioritize reliability, safety, and lifecycle cost reduction, demand for advanced vibration control systems is expected to grow. Integration with digital twins and condition monitoring platforms will further enhance system effectiveness and value. Long-term growth will be supported by continued industrial expansion, infrastructure investment, and adoption of predictive maintenance strategies.

Conclusion

The vibration control system market is a vital enabler of safe, efficient, and reliable operation across industrial, infrastructure, and transportation applications. Driven by industrial growth, infrastructure development, and increasing focus on equipment protection and comfort, the market continues to expand steadily worldwide. While challenges related to cost, complexity, and maintenance persist, technological innovation and emerging market demand are creating strong growth opportunities. As systems and structures become more advanced, vibration control solutions will remain essential for performance, safety, and longevity.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jeux

- Gardening

- Health

- Domicile

- Literature

- Music

- Networking

- Autre

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness