What Maintenance Keeps VMC Machines Running

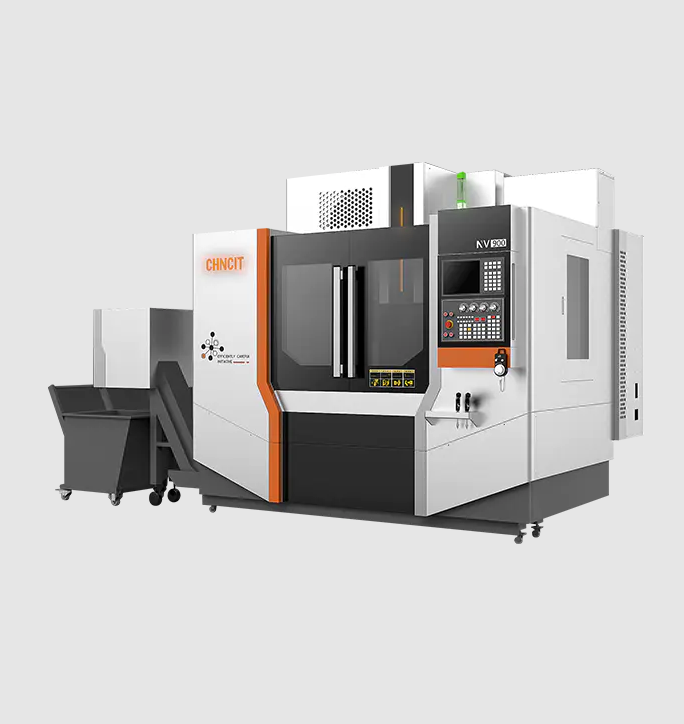

Maintaining a Vertical Milling Centers setup is a continuous process rather than a one-time task. Whether you run a VMC machine Factory or a small machine shop, consistent maintenance routines significantly enhance performance, reduce unexpected breakdowns, and extend the machine’s life.

A core part of VMC maintenance is regular inspection of mechanical components. Checking ball screws, linear guides, bearings, and belts for wear helps catch wear early. Replacing worn parts before failure reduces the likelihood of machine stoppages and preserves accuracy.

Coolant and hydraulic systems require particular attention. Leaks, declining fluid levels, and buildup of coolant sludge can impair circulation and cooling, which affect machining quality and spindle life. Inspecting hoses, tightening connections, and cleaning coolant tanks improve fluid dynamics and heat removal.

Alignment and calibration are routine tasks that affect precision. Machines can drift due to temperature changes, heavy use, or vibrations. Periodic calibration and checking worktable flatness ensure the Vertical Milling Centers maintain dimensional accuracy throughout production runs.

Chip management is another vital aspect of maintenance. Chips left in the work area can cause abrasion, sensor blockages, and interfere with cutting operations. Using conveyors, air blasts, and effective coolant flow helps keep chips clear. Additionally, cleaning chip paths and houses prevents recirculation of debris.

Electrical systems also demand checks. Loose connections, worn cables, and dust buildup in control cabinets can lead to intermittent errors or control failures. Keeping electrical panels clean and ensuring secure connections help maintain consistent machine control and reduce unexpected faults.

Ultimately, a well-managed maintenance protocol improves reliability and safety. By combining regular inspections, fluid system care, tool monitoring, and calibration, operators can keep their VMC machines producing accurate parts with fewer disruptions — a key reason why experienced shops emphasize preventive care.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Giochi

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Altre informazioni

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness